Single Torsion Spring Replacement

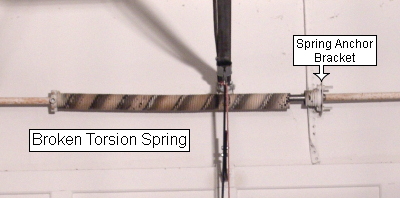

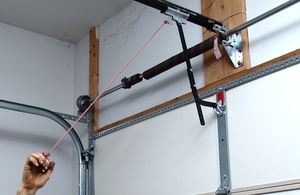

The following instructions for fixing garage door springs are for do-it-yourself homeowners and for maintenance repair men who service their smaller commercial or industrial overhead doors. They are written to help the DIY homeowner and maintenance repair men replace a torsion spring that is mounted on one side of an anchor bracket above the middle of the garage door as pictured above. This is a right wind spring mounted on the left side of the spring anchor bracket. Springs mounted on the right side of the bracket are normally left wind. If you have two springs mounted above your garage door, see our standard torsion spring replacement tutorial.

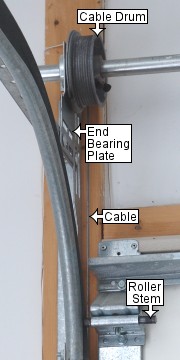

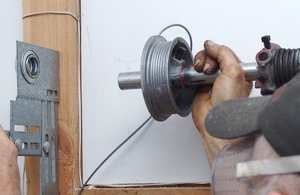

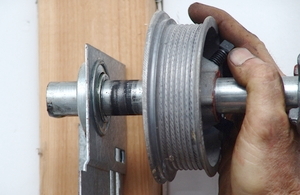

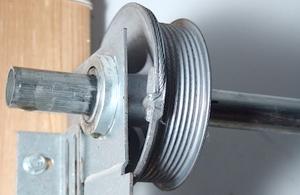

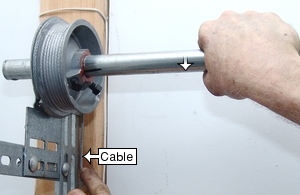

Your cable drums and cables should look similar to those in the picture below. The next part beyond the end of the spring assembly is the cable drum. The drum is cast aluminum alloy 4" in diameter and 13" in circumference around the flat portion. Just beyond the cable drum is the end bearing plate. The cable unwraps off the back of the drum between the drum and the garage wall or jamb and travels down beside the door, inside the track brackets and behind the roller stems as shown.

If your spring assembly is different from this, parts of these instructions may be helpful, but other parts may give dangerous, inaccurate instruction and waste a lot of your time.

For example, low headroom garage doors often have cable drums on the outside of the end plate and the springs usually wind down rather than up. They normally have left wind springs mounted on the left side of the spring anchor bracket and right wind springs mounted on the right side of the bracket. The first part on the shaft beyond each torsion spring is the end bearing plate. Just beyond the end bearing plate is the cable drum. On these the cable often runs on the front of the cable drum. The bottom of the cable is attached to a bracket that wraps around the front of and outside the vertical track.

Another example is the Clopay EZ-Set Torsion Spring System for garage doors. While Clopay has made great strides in developing a safe system for the do-it-yourselfer to install, replacing these garage door springs can be very difficult.

On one of our tutorials we have provided several options for replacing E-Z Set springs. In another tutorial, you will find instructions for replacing EZ Set torsion springs with specially manufactured aftermarket springs. In addition, one of our customers has provided excellent instructions for removing the spring without wrecking the winding unit that secures the stationary cone. Instead of a spanner tool, you may prefer to use a pipe wrench or large channel locks to hook the end of the spring and remove it from the cones in the last step.

Older Crawford garage door springs are different and the counterbalance hardware is unique. A special page has been provided to use in conjunction with this page.

If your spring just broke and you are looking for instructions to decide if you can change the spring safely and correctly, this page should help. DO NOT OPEN AND CLOSE YOUR GARAGE DOOR. Wood doors are heavy and will probably damage or ruin the opener. The tops of steel garage doors often bend when operated with a broken spring.

For more information on how to install torsion springs I recommend you visit Richard Kinch's page titled, "How I Replaced Deadly Garage Door Torsion Springs and Lived to Tell the Tale." Richard is a brilliant engineer who has provided a wealth of technical information on fixing garage door springs along with valuable advice regarding some of the schemes unscrupulous garage door companies use to rip people off.

If you have decided to change your springs and you are ready to buy new ones, we recommend you gather five pieces of information: torsion spring dimensions, garage door weight, garage door model and size, track radius, and the cable drum number or circumference on the flat portion. Links to the left will help you gather that information. From my own experience I would guess that at least 10% of the garage doors have the wrong springs on them, and many more could be improved. I have also found that most people - even garage door technicians - have difficulty measuring torsion springs. This additional information has prevented many incorrect orders over the years.

Getting Started: Safety First!

As with our torsion spring price lists we begin these instructions with our sternest warning:

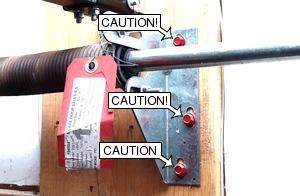

CAUTION! Torsion spring replacement is dangerous because installing the new spring puts it under tension. If you do not use the right tools and follow safe procedures, you could lose fingers, limbs or even your life. You could also damage property. We want your business, but not at the expense of your well being. Doing the job right is your responsibility. If you have any doubts about your ability to perform the work safely, we recommend you hire a professional to repair your garage door.

The following procedures are based on my 26 years in the garage door industry. In spite of my high mechanical aptitude, even after 18 years in the business I lost the end of my left index finger. A few years later I had five stitches in my right thumb, and a year later five stitches in my left thumb. In the last year the emergency room staffs have dug steel out of my eye and sewn up my ring finger with eight stitches. The best I can do is help you minimize the risk of injury; that’s all I can do for myself. I am not so naive to think that I have made my last trip to the emergency room. Repairing garage doors is dangerous work.

It is impossible to cover every dangerous situation you may encounter. The directions below hopefully will help guide you in safely replacing your garage door springs, but there are no guarantees. Pay special attention to the warnings that appear in red.

| 1. Two important assumptions will help you perform this work safely. First, assume that the garage door spring is going to break as you unwind or wind it. To avoid injury clutch the bars firmly on the ends furthest away from the plugs and stand securely on a sturdy ladder, not on chairs or cans turned upside down. Keep clothes and body parts away from the spring. Wear safety glasses. |  |

| 2. Second, assume that the plug is going to slip or explode as you wind the spring. Keep your head out of the path of the winding plug. Keep your hands away from the plugs so that if and when the winding bar slips out of the plug and your hand jerks up, the plug doesn't rip your flesh or wrap your clothes and body parts into the spring. |

| 3. Beware of older winding cones. We recommend replacing them with standard cones when ordering a new spring. These older Crawford and McKee garage door cones were made for 5/8" bars. But sometimes the holes are too small for 5/8" bars. Whatever you do, don't use a 1/2" bar; instead, grind down the 5/8" bar to fit. I recently had a McKee spring let loose after winding because I used a 1/2" bar when my 5/8" bar wouldn't fit. Just before it let loose I was telling myself, "This is not safe." And it wasn't. |  |

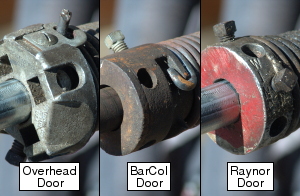

| 4. Older Overhead, BarCol and Raynor winding plugs often have inconsistent hole sizes. Therefore, we recommend that you purchase standard cones (which have normal hole sizes) when you order your torsion spring. If you insert a 1/2" X 18" bar in some of these holes you can move the opposite end of the bar over four inches. Bars in newer cones move less than 1 1/2". I've had many of the older cones spin loose from my bars, the last one generating an $1800 emergency room bill. If your cones are like any of these, or if they have more than 2" of play, get new cones or leave the job of installing torsion springs to a professional garage door mechanic. |

| 5. To begin, gather the tools you'll need. You'll need a minimum of one or two 10" vise grips, an adjustable wrench, and two 1/2" X 18" winding bars. Most hardware stores sell 1/2" X 36" steel rods that can be cut in half. You'll also need a firm ladder. A ruler and a file may also be needed, and a socket wrench and sockets would shorten the time required. Finally, make sure your garage is lighted well. |  |

| 6. Unplug the power cord to the garage door opener. Some older openers are hardwired and you will need to remove a fuse or flip the circuit breaker. |

| 7. Disengage the opener from the door. Some door openers have a neutral position for the trolley disconnect. On older openers you may need to remove the L-shaped drawbar arm. |  |

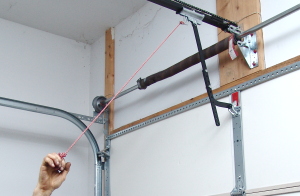

| 8. Vise grip the vertical track about 3" above one of the rollers. If you install the wrong springs, or if you over-wind the spring, this will prevent the garage door from flying up and knocking you off your ladder after winding the spring. This has happened to me on more than one occasion. |

| 9. Measure your broken spring and your new spring to make sure you have the correct spring. For information on measuring your springs, go here. |  |

| 10. Lay the new spring on the garage floor or work bench and measure the length, inside diameter, and 20 coils to determine the wire size. Check the wind on both your broken spring and your new spring to ensure that they are the same. If you are converting from a different spring system, and if you have a left wind spring, you will need to install the spring on the right side of the spring anchor bracket. If you have a right wind spring, you will install the spring on the left side of the bracket as we are doing here. |

| 11. Loosen the set screws on the broken torsion spring using a wrench. |  |

| 12. Check to make sure the spring bracket is secure. Tighten the lag screws if needed. If loose, replace with longer or thicker lags. Never touch these when the springs are wound. One of my customers removed the screws when the springs were wound. He broke his arm in 14 places and almost died. He spent a month in the hospital. |

| 13. Remove the two bolts that secure the center stationary cone to the spring anchor bracket. |  |

| 14. Separate the broken spring from the center bracket. |

| 15. If the spring bracket is slotted, vise grip the bracket to secure the shaft in the bracket. This will keep the shaft from possibly falling out and causing injury or damaging the garage door or shaft. One of the stationary cones usually has a nylon bushing in it. Remove the bushing from the cone and leave it on the shaft next to the center spring bracket. |  |

| 16. Slide both parts of the spring away from the spring anchor bracket and toward the cable drum. If it will not slide, loosen the set screws more. If the shaft is distorted because the garage door installer overtightened the set screws, file the shaft, insert a bar into the plug and tap the bar with a hammer until the plug passes over the enlarged portion of shaft. |

| 17. Go to the cable drum on the opposite side of the broken spring. Wrap the cable tightly around the drum. Mark the shaft and drum using a permanent marker or a file. You will need this mark to level the garage door after the new spring is installed. |  |

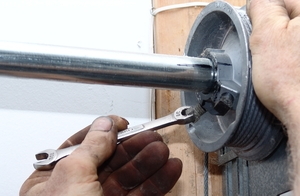

| 18. Loosen the set screws on this cable drum. |

| 19. Slide the cable drum away from the end bearing plate. If the end bearing plate is leaning, brace it with angle or lumber. |  |

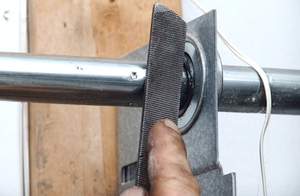

| 20. Examine the bearing and shaft. If the bearing has worn ridges into the shaft or if the set screws have left raised metal, file the shaft. Ridges in the shaft indicate worn or dry bearings. You will inspect them later. |

| 21. Go to the other cable drum and repeat this process. Start by wrapping the cable around the drum and marking the drum and shaft. |  |

| 22. Loosen the set screws on the drum. |

| 23. Slide the shaft out of the end bearing plate. |  |

| 24. Remove the cable drum. You may need to loosen the set screws a little more. |

| 25. File the shaft here as needed. |  |

| 26. Slide off the old spring. If you are thinking of reusing your cones, you can find instructions at our tutorial page by clicking here. |

| 27. Inspect the bearing. Lube it with motor oil, spray lithium, or spray lubriplate grease. Do not use WD-40. If the shaft is worn and the bearing is seized and you can't free it, replace the bearing. If you have bearings marked "ADH" we recommend replacing them. I find very few other bearings that need to be replaced. However, if you do need to replace the bearing and you do not have a new one, you can replace it at a later date. A quick way to do this can be found at our tutorial page. |  |

| 28. Slide the stationary cone onto the shaft as shown in the picture. If the cones are already installed, slide the spring on the shaft leading with the stationary cone and proceed to step number 31. |

| 29. Slide the new spring on the shaft. |  |

| 30. Slide the winding cone on the shaft. You may need to loosen the set screws for it to go on the shaft. |

| 31. Slide the cable drum on the shaft. The cable does not need to be on the drum at this time. |  |

| 32. Insert the shaft into the end bearing plate. |

| 33. Slide the spring and cones toward the center of the door. |  |

| 34. Align the marks on the cable drum and the shaft that were made earlier. |

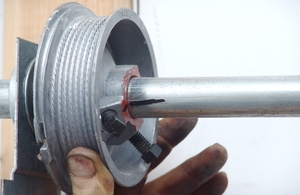

| 35. Finger-tighten the set screws into their original indentations. Rotate the drum as needed to find the slots. |  |

| 36. Try to turn the drum on the shaft. It should not turn if you have finger-tightened the set screws properly into the original grooves. If you did not mark your drums and you can't find the original indentations in the shaft, finger-tighten the set screws until the screws meet the shaft. |

| 37. Tighten the set screws an additional 1/4 to 1/2 turns. Add an additional 1/4 turn if you could not find the original setscrew indentations in the previous step. Heavier wooden garage doors may require an additional 1/4 turn. Caution: Under-tightening the drums could cause the drum to slip and the door to cock or fall. Over-tightening the set screws could damage the shaft or drum, resulting in the same problems. This is a critical step. |  |

| 38. Slide the shaft toward the end bearing plate until the cable drum is flush against the race of the bearings. |

| 39. Bend the end of the cable at a 90-degree angle. |  |

| 40. Insert the cable into the slotted part of the drum and wrap the cable around the drum. |

| 41. Twist the shaft to tighten the cable on the drum. |  |

| 42. While twisting, vise grip the shaft as shown to keep the cable tight on the drum. The top of the vise grip should be tight against the garage header. This will keep the cable on the first drum while you install the cable on the other drum and position it in place. It also keeps the shaft from turning and the cables peeling off when you wind the spring. |

| 43. If you wound the cable correctly, it will be taught as it comes off the cable drum. |  |

| 44. Go to the other side of the garage door. Bend the end of the other cable at a 90-degree angle. |

| 45. Insert the cable into the slot of the drum, and rotate the drum until the cable is tight. |  |

| 46. Slide the drum against the bearing and push the shaft to the left. The marks should line up. If they don't, determine why and correct the problem. One common problem is that one of the cables gets stuck on the lock striker, a track bracket bolt, or the end of a reinforcing strut. It could also be caused by a garage floor that may have shifted, or the vertical angle that helps support the bearing plate may have loosened and shifted. In addition, many garage doors have been installed with a gap between a drum and a bearing plate. The cable drums should always be flush against the race of the bearings. One common problem if this is not done is that one of the springs will bind and the garage door won't close all the way. |

| 47. Finger tighten the drum set screws until the drum will not turn. |  |

| 48. Tighten the set screws an additional 1/4 to 1/2 turns as on the other side. |

| 49. If you have a slotted center bracket, remove the vice grip and lube the shaft where it turns inside the bushing. |  |

| 50. Otherwise, oil the bearing as needed. If the shaft has ridges from the bearing, file them. The shaft needs to be free to slide sideways inside the bearing. This bearing keeps the shaft from rubbing against the inside of the stationary cones. Some garage doors are installed without bearings. If you have no bearing in your spring anchor bracket, grease the shaft where it will be rubbing inside the cones. |

| 51. Slide the stationary cone to the spring anchor bracket and install the bolts. Finger-tighten the nuts until the stationary cones are flush against the spring anchor bracket. Forcing the cones by tightening the bolts may break a cone if it is catching on a bearing. Winding a spring with a cracked cone could cause the spring to spin loose and the bar to fly. If necessary, install washers between the plugs to protect them from breaking. I've had to do this on many Windsor and Raynor garage doors that have wider bearings. If your spring already has the cones installed, bring the whole spring to the spring anchor bracket. |  |

| 52. Secure the bolts. If your spring already has cones installed, move to the winding cone and jump to step #65. |

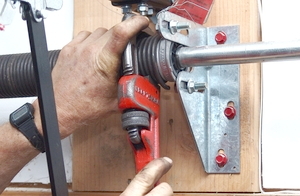

| 53. Grip the spring and twist it onto the stationary cone. You can usually wind it about 2 turns by hand. |  |

| 54. Using a pipe wrench, grip the 4th, 5th and 6th coils away from the end of the spring and pull down. |

| 55. If one of the bolts is in the way of the spring, remove the bolt and insert only the end of the bolt into the stationary cone from the opposite side. This will keep the stationary cone on the spring anchor bracket. |  |

| 56. Continue until the spring is wound completely on the cone. If you removed a bolt to install the stationary cone, reinstall the bolt. |

| 57. Move to the winding cone. Screw the cone about two turns into the torsion spring by hand. |  |

| 58. Insert a winding bar into one of the holes of the winding cone. |

| 59. Continue to wind the cone onto the spring another two turns. Pull down on the winding bar. Insert the second winding bar into the plug, remove the first winding bar, and pull down on the second winding bar. Continue until the cone no longer tightens. |  |

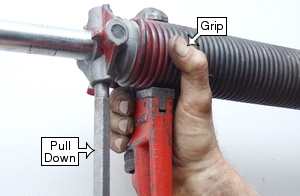

| 60. Insert a winding bar into a hole on the top of the winding cone. |

| 61. Insert the 4th, 5th and 6th coils into the jaw of the pipe wrench. |  |

| 62. Holding onto the pipe wrench in one hand, grip the spring between your thumb and the pipe wrench, and pull down on the winding bar. |

| 63. Release your grip on the spring and bring the winding bar back above the spring. |  |

| 64. Repeat the previous two steps until the spring is fully wound on the cone. You are almost ready to wind the spring. |

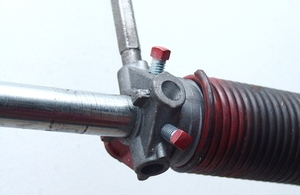

| 65. Before winding the spring, I recommend marking the shaft just beyond the winding plug. This is a final step taken to assure that you have installed the correct spring on the correct side of the spring anchor bracket. Torsion springs always grow in length when they are wound in the proper direction. If your spring does not grow as you wind it, you are winding it the wrong direction probably because it is improperly installed. We frequently get calls about springs coming loose from the cones at about 6 turns. If this happens, you have the wrong wind spring and need to install it on the other side of the door.. |  |

| 66. Tape your winding bars, not only to assure that you are inserting the bars completely into the cones as you wind the springs, but more importantly to assure that the bar does not slip out of the cone when you stretch the spring at the end. This has happened to me several times. We stretch the springs after winding them because the shaft floats horizontally between the flexible end bearing plates as the door operates. Although this may be as little as 1/4" the binding of the coils as the door closes often keeps the door from closing completely, especially when the springs and bearings are dry. |

| 67. At this point you will wind the springs. Many garage door servicemen mark the springs with chalk or paint, but you can probably wind the springs in the time it would take me to explain how to read the marks. You will be winding up on the torsion spring. Begin by turning the spring up 1/4 turn until it meets resistance. This is your first quarter turn. Count "one." Next, insert the bar and raise it 90 degrees. Insert the second bar. This is "two." As you wind the spring it should grow in length the thickness of one coil for every turn. |  |

| 68. Raise the second bar 90 degrees and insert the first bar. This is "three." Continue winding. If the spring shortens in length, unwind the spring and switch sides - the spring is on the wrong side. Otherwise, continue winding until you reach a count of "30." This is 7 1/2 turns, which is normal for most 7' garage doors. Newer steel doors with only one strut on top often need only 7 1/4 turns. On 8' doors count to 34. Each time you insert a bar into the winding cone, listen for the click to let you know the bar is in all the way. Not inserting the bar all the way could cause the plug to explode. |

| 69. If the spring comes loose from the plug at about 6 turns, you are probably winding the spring backward because you have the wrong wind spring. Put the spring on the other side of the spring anchor bracket. Otherwise, after winding the springs, you will need to stretch the springs and secure the winding plug. This can be very difficult, and it can be especially dangerous. On several occasions I have had the winding bar slip out of the plug while tightening the set screws. Having the bar marked with tape next to the plug can help to prevent this from happening to you. |  |

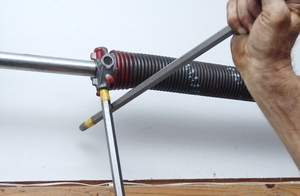

| 70. Mark the shaft 1/4" beyond the winding plug with permanent marker or with a file. We stretch the springs because the shaft floats horizontally between the flexible end bearing plates as the garage door operates. Although this may be as little as 1/4" the binding of the coils as the door closes often keeps the door from closing completely, especially when the springs and bearings are dry and need lubrication. |

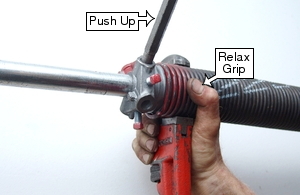

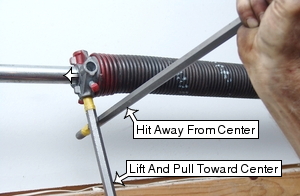

| 71. Here you will need to do three things at once. With your left hand, lift the bar just off the top of the door and pull it toward the center of the garage door. While lifting up and back, tap the top of the bar just under the winding plug with your other bar. Pulling the bar back toward the center of the door as you tap causes the spring plug to bind on the shaft and not slip back. |  |

| 72. Continue tapping until the plug moves out to the mark on the shaft. Continue holding the bar off the door and pulling back toward the center of the door. If the plug slips away from the mark, repeat this step. Keep an eye on the tape to make sure the bar doesn't slip out of the cone. If it does start to slip, rest the bar against the top of the garage door, insert a bar in the next hole and turn the plug up enough to allow you to push the marked bar back into place. |

| 73. After the plug reaches the mark, continue pulling the bar off the door and back toward the middle of the door with your left hand. Tighten both set screws 1/2 to 3/4 turns each after each screw first meets the shaft. This is the point at which you will feel the screw meeting resistance. |  |

| 74. Carefully test the set screws by pulling down on the bar. The winding plug should be tight enough so that when you pull down on the bar, the garage door should begin to lift. If the bar starts to slip when you pull it down, add 1/4 turn to each set screw. CAUTION: Before removing the bars from the plugs after securing the winding plug, you will need to run an important test of the door. Many of the accidents that occur while fixing garage door springs are due to installing springs that are too strong. |

| 75. Slowly pull down on the winding bar until the garage door rises 3" and the roller hits the vise grip on the track. The door will usually drop back down and raise the bar. If it doesn't drop back down, lift the end of the bar until the door closes. If the door comes up by itself when you hold the bar lightly, the springs are either over wound or they are too strong. You may need to remove 1/4 to 1/2 turns from the springs. |  |

| 76. If the door stays on the floor, remove the bar from the cone. |

| 77. If the door stays on the floor by itself, remove the vise grip from the track. If the door is off the floor and the roller is against the vise grip, close the door with one hand and remove the vise grip with the other. If the springs are too strong, you have to restrain it from flying into the open position. |  |

| 78. Remove the vise grip from the shaft. |

| 79. Raise the garage door slowly. Check the door balance. The door should stay down when closed, halfway when opened halfway, and open when opened. You may need to adjust the spring. If so, secure the vise grip to the shaft as before. Add 1/4 turn of tension to the spring if the door will drop to the floor by itself from the halfway point. If the garage door won't stay on the floor, and if it pulls itself up when stopped halfway, close the door and remove 1/4 turn of tension from the spring. |  |

| 80. Oil the spring. The thicker the oil the longer it will last. I normally use 40 wt. motor oil, but 10W40 will do if that is all you have. Squirt a stream of motor oil across the tops of the springs and rub the oil into the coils. Do not oil the last inch of each end |

| 81. Check the garage door at the floor. It should seal all the way across. If it doesn't you may need to adjust the drum on the higher side to get the door to level. Click here for information on how to level your door if it is up on one side. |  |

| 82. Reengage the garage door opener. |

| 83. Plug in the power cord for the opener. Adjust force and travel as needed. |  |